|

1963 Z06 and 1964 J56 Corvette Kelsey Hayes

Master Cylinder

Here we have one of the very rare and valuable 1963 Z06/1964 J56 master cylinders.

We're told it was "rebuilt" by a production rebuilder, but failed to work

properly. The owner sent it to Drew and Noland at

Corvette Stop. They sent it to me to

troubleshoot and repair. 199 of the Z06 Corvettes and 24 of the J56 Corvettes were built.

We have a little more information about the Z06/J56 master cylinder, with photos

of the cylinder in cars,

here.

Note the diagonal feature in the casting, between the outlets, that rises

toward the reservoir. There is a drilled hole from the forward end of the

cylinder through this feature that connects the end of the bore to the

reservoir.

The next two photos show the counterbore at the forward end of the cylinder

which connects the channel from the reservoir with a hole at the bottom of the

bore, and the other end of the channel in the reservoir. This cylinder has

been carefully hand-blasted to preserve the remains of the original zinc dichromate finish

and the patina of 40 years, rather than cleaning it to bare metal in our shot-blasting machine.

The expansion plug must be removed as shown for proper cleaning. The original

plug is still a tight fit, and will be re-installed with a sealant after the machine work is completed.

The fluid in the area covered by the plug is exposed only to the pressure

developed by the standing fluid in the reservoir.

|

|

After disassembly, the first thing we look at is the bore. It's not easy to

get a good shot down the bore, but minor pitting and rusted

areas can be seen in the photo, below left. The pitting is bad enough to cause

abrasion of the seals which would undoubtedly result in failure of the cylinder

after a few hundred applications, but it is not bad enough to keep the cylinder

from working at least fairly well with new seals. The next thing we look at is the piston assemblies

and seals, below right.

|

|

|

This is an unusual cylinder. The primary piston assembly, to the left in the

photo above right,

would be very typical in a single-circuit master cylinder, but this type with

the unrestrained spring is rarely found in a dual-circuit cylinder. The

secondary piston and spring assembly are also quite unique. There is a rubber

seal at the right end of the spring assembly that closes a hole in the center of

the end of the bore as the pedal is depressed, shutting off the fluid path to

the reservoir and directing it to the outlet. The hole and valve sealing surface

around it can be seen in the photo, above left. This type of piston and valve is

frequently seen in Little British Car cylinders made by Dunlop and Girling, and

we've shown the equivalent parts from a Dunlop cylinder in the next photo, below left. When the

brake pedal is released and the return

springs are at full extension, the rubber end seal is pulled within its

housing so fluid can travel past the seal to and from the reservoir through the

hole at the end of the bore. When pedal pressure begins to compress the

return springs, the seal is supposed to extend from the housing, closing the

end hole and thus forcing fluid out a side port and to the brakes. The photo

to the right shows the slightly compressed condition. The rubber seal in the

Dunlop valve at bottom can be seen to extend from the valve body, whereas the

seal in the Kelsey Hayes valve on top remains within the housing.

|

|

|

In the photo below left the small spring that causes the Dunlop valve to

extend can be seen on the valve rod. I've manually shifted the Kelsey Hayes

valve rod to the right to show its rubber seal. The photo below right shows the

Kelsey Hayes assembly taken apart, with no small spring to be found.

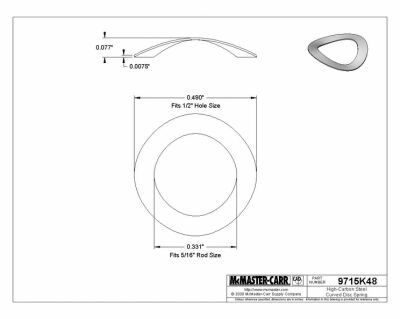

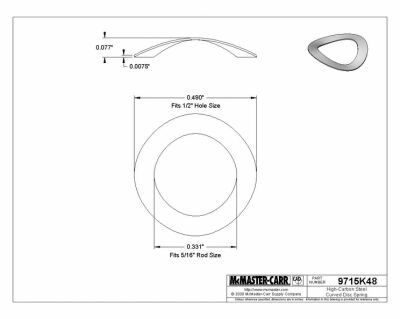

The Kelsey Hayes assembly obviously requires a wave or spring washer, since

there is no room for a coil spring as used in the Dunlop assembly. The photo

below left shows approximately what the extension of the seal will be with the

wave washer installed. I ordered wave washers, below right, from

McMaster-Carr that are a perfect fit.

|

|

|

Now on to other problems. The secondary piston must accept fluid pressure in

the form of a column of fluid pushed toward it by the primary piston, and must also

push ahead of it another column of fluid to be directed to the secondary outlet.

Most dual-circuit master cylinders use a secondary piston with two lip-type seals

installed in separate grooves in a back-to-back orientation. This secondary

piston carries only a single seal--the other groove is a manufacturing artifact

rather than a seal groove. But a lip-type seal like the one that came in the

cylinder, below left, will only capture fluid in one direction--fluid will

bypass in the other direction. The lip-type seal will appear to work correctly

(in the absence of other assembly defects) but if there is a failure resulting

in loss of pressure at the secondary outlet, fluid will bypass all the way

through and out of the cylinder, causing complete brake failure rather than the

loss of one end only as should be the case with a dual cylinder.

Since this cylinder did have "other assembly defects" in the form of the

incomplete secondary spring assembly, it would have been impossible to develop

pressure at either outlet. Fluid moved by the primary piston would bypass the lip

seal on the secondary piston, and flow past the open valve seat at the bottom of

the bore and return to the reservoir. The reservoir is a single chamber with a

divider, so the fluid will simply circulate through the cylinder without

building pressure at either outlet.

An o-ring will seal in both directions, and--lo and behold--a standard 1"

brake cylinder o-ring is a perfect fit in the groove. The o-ring looks right at

home in the photo below right.

We're getting closer to a functional cylinder, but one issue remains.

The primary seal that was on the primary piston, at top in the photo below left,

has an ID that is larger than the post on which it fits. This allows fluid

to bypass between the post and the seal, and and prevents pressure from building

at the primary outlet. We installed the lower seal, with a smaller ID, as the

last of the assembly fixes. These corrections—in conjunction with a brass

sleeve to repair the cylinder bore—will result in a cylinder that will work as

well as a new one, and last longer.

We have one more comment--it is absolutely inexcusable for a rebuilder to use

a pipe wrench on any cylinder, let alone on a

cylinder for such a rare and valuable car. See the jaw tooth marks on the outlet

adapters, below right. Such practices do not occur in our

shop.

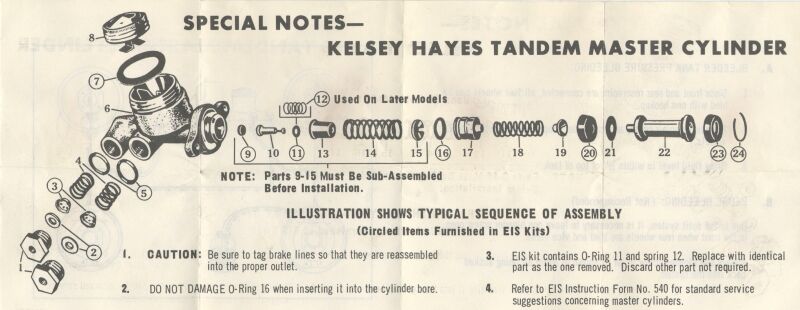

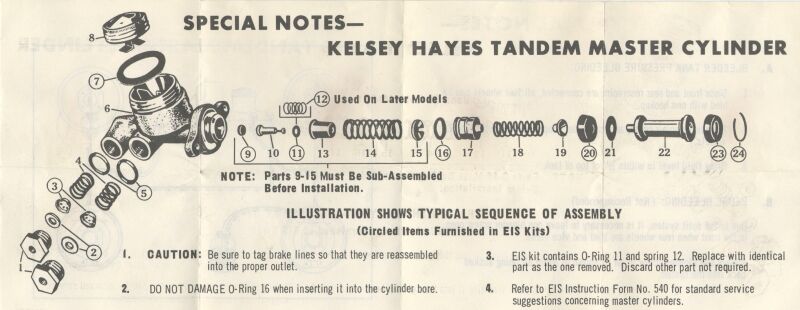

After we wrote this webpage detailing our conclusions about the condition of

this cylinder, we were fortunate to contact a Z06 owner whose master cylinder is

out of the car and apart, and who has an old-stock EIS rebuild kit and instruction

sheet with an exploded view of the internal parts. We were delighted to find

that our conclusions were exactly correct as verified by his original parts and

by the parts in the rebuild kit.

Here's a scanned image of the exploded view from the EIS rebuild kit. Note #3

refers to "O-ring 11 and spring 12" and the illustration indicates that spring

12 is used on later models. However, the rebuild kit and the owner's cylinder

both contain wave washers rather than o-rings or springs.

Click on the image to see the full-sized scan. (In some browsers, it may be

necessary to click again to get the full scan.)

We're pleased to announce that we can supply all of the "consumable" parts in

this cylinder except for the valve seal in the secondary piston spring assembly.

Fortunately, this seal does not operate in a manner that causes significant

wear, so it is quite likely to be in good condition.

|